|

|

|

||||||

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

December 2006 November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

Project Archive: Dogwood Windows

Sunday, May 21, 2006: Back in the Saddle?

Hi there. Remember me? I used to do stained glass. That was three years ago, with only a brief, hurried relapse two years ago, when we were preparing our old house for sale and it became apparent that finishing up the last transom installation could be procrastinated no longer. I dug the last of the three transoms out of the basement, puttied it with a quickness, got Don to frame and install it, and then we sold it (and the rest of our cute little bungalow) to a nice young couple from Dupont Circle. At closing, the nice young couple went on and on about the many renovations that had been done to the house, including the previous owner's kitchen remodel and inventive exterior paint, plus Don's picket fence and built-in bookshelves, but with no mention of the transoms over which I sweated lo these many hours. I choose to believe it's because they mistook them for original to the house. Yep, that's the ticket. I never did finish the tiered lampshade I abandoned three years ago this month. Going back to school got me off-track, lack of momentum kept me there. One day, maybe. The lampshade lives in its 85-percent-completed form in the basement of our new house. The new house does not bring the cute the way the old house brought the cute. But we're working on it. The first task was a badly-needed kitchen remodel (before; after). The company who did it for us did a good job, except for neglecting and neglecting to brick up the old stove fan. They have been telling us for a *year* that they'll get to it. But if the molded-plastic vent cover on my outside wall is the biggest complaint I have with the new kitchen? I have no room for complaint at all. As Don observed, the old kitchen was good for nothing except a place to put the Chinese takeout. The kitchen work finished, I then repainted the entire first floor, with the exception of the bathroom, which was in a state similar to the kitchen's when we first bought the place, i.e.: nothing worth saving; this is a job for the professionals. That was going to be our next project. And then we bought a Siberian Husky.

Those of you who know huskies can see where this is going. The breed is insanely high-energy, and especially as puppies, can be very destructive if they get bored. When Tashi was seven months old, we smartened up and adopted another husky to keep her amused, which may be the only reason our new house still stands today. Even so, most of our project-type energies in the last fourteen months have been devoted to fortifying the house and grounds against the sort of abuse a husky can dish out. For example, a six-and-a-half-foot stockade fence was needed in the back yard when the three- or four-foot chain link that had been there didn't even slow Tashi and Shadow down whenever they would get an exploring itch. And of course there was the pressing need to replace the couch that Tashi ate. Fortunately, Don had just the answer to that particular problem. For a year or more, he'd been periodically trying to convince me that I liked the look of a mission-style sofa for which he had woodworking plans, from a book of DIY mission projects. Each time the subject was broached, I artfully deflected. "All that wood, it doesn't look comfortable." "When do you have time to build something like that?" "We have a perfectly good couch already." When we no longer had a perfectly good couch already, I no longer had a leg left to stand on. And so Don bought a small forest's worth of mahogany, and built us a new, mission-style couch.

The couch is just about done now. Don wants to put one more coat of finish on the wood, and possibly also add, on each side panel, a little stylized dogwood motif he designed and cut out of holly (for the white petals) and I think walnut (for the dark center). But even if those things never happen, the couch is done enough to sit on. Shortly after the couch was made sittable (and in fact more comfortably so than one might have initially believed), we were so taken with the new look of our living room that we ripped out the cute, but very dark-making plantation shutters that had infested the first floor of our house when we bought it. What a difference that made to the feel of the living room: no longer a sullen cave, but an airy nest of domestic delight! (The less-vomitous-than-previously shade of yellow in which I repainted the living room last year helps, too.) Once we had some sunlight in that room, I suppose it was just a matter of time before I decided we needed some stained glass. Something incorporating Don's dogwood motif. Something, I am thinking, that might look like this:

Monday, May 22, 2006: The Part Where Mistakes Can Be Made Without Breaking A Thing

Went glass shopping for my dogwood window project yesterday. I planned to use some stuff out of my scrap glass box, but needed to buy quite a lot of new stuff anyway. It was a Sunday, and Weisser Glass wouldn't be open again until Tuesday, and I just couldn't wait. So off to Virginia Stained Glass I went. I hadn't been there in probably four years. I think the store got smaller. Literally. It's in the same place but I think the shop next to it in its little strip mall used to be space taken up by the glass store. Fortunately, it's still impossible to get a smile out of any of the staff there: thus reassured that I was in the right place after all, I commenced a vigorous browse. When I did the Photoshop mockup of my design, I did my usual trick of swiping real glass samples off the various manufacturer's websites. Spectrum still has the best samples, hands down, and even provides an FTP site where you can download them all en masse. Bullseye's samples are the least useful. You have to download their catalog in PDF, and then for each color of glass it shows you tiny chips of like four shade variations, and the textures aren't shown together with the actual colors, so there's a lot of imagination necessary there, and imagination doesn't port well to Photoshop. I ended up with colors pretty close to those I used in my Photoshop design, and interestingly enough, the colors look vastly less harmonious just laid out on a table next to one another than they do in my Photoshop document.

See? That's not a collection of colors you'd just pick, out of context, to go together. Somehow it seems to work in my design comp though. Uh, fingers crossed. Another design decision fraught with peril: am mixing opaque and non-opaque glasses with abandon here. I've never done that before. The greens and cream are pretty solidly opaque; the purple is a "wispy" glass that's fairly translucent; the red is a nice clear cathedral glass; and the crinkle pattern on the clear glass doesn't even provide the level of opacity you'd expect out of a shower stall door... so I'm running the gamut here. For seven square feet of clear, two of purple, and one of green, the bill was going to be seventy-five dollars. (Now I *have* to build these windows...) But lo and behold, I had in my wallet a beat-up old Virginia Stained Glass punch card, which entitled me to $25 off after spending $250. When I got distracted from glassing three years ago, the card was punched up to $210. So check me out: three years later, I got $75 worth of glass for $50. A victory in the name of wallet packrats everywhere. Tuesday, May 23, 2006: Soon Turned Out, I Had A Heart Of Brass

Today I stopped in to the The Art League School annex in Old Town Alexandria to see if I could find Jimmy, who taught a couple of classes I took back in the day. I wasn't sure whether he'd remember me, but way back then he'd said "Stop in whenever if you have any questions or anything." I didn't know if he necessarily had in mind "three years from now" but I was concerned about some design/construction issues with my new project, so: road trip! As it turns out, he remembered me: this website may have helped. He said he'd found it just recently. So everyone say hi to teacher! Having maintained a web presence for going on eleven years now, I realized tonight how nice it is to hear the words "I found your website" and not have to wonder if I wrote anything embarrassing involving the finder. (I'm 99 percent sure I didn't: allow one percent for the recent comment about unsmiling staff at a certain glass shop where Jimmy once gave classes, and still may for all I know.) My clear conscience owes no debt to any particular prudence or virtue on my part; it's just that he's such a nice guy and so good a teacher that I can't imagine having had anything other than good things to say about him. A case in point. The dogwood windows I want to build are 33 inches high by 14.75 inches wide. This seemed to me to be just about big enough that I'd need to use steel reinforcing bars, or rebar, in construction. Problem: I know nothing at all about using rebar. I went to Jimmy to find out if there was some way he could ease my troubled mind. I did not leave disappointed. I showed him my design, and some photos of the room where I want to install the finished product. His first take on the situation was that, yeah, I'd want a horizontal length of rebar on each window. No surprise there. The bad news was that for structural reasons, the rebar would want to be on the *inside* of the window. The other bad news was that the rebar would want to be notched about an inch deep into the window frame on either side of the glass. Here is where I began to have some doubts as to whether this was a good idea. Hacking up window frames sounds scary ("scary" and not "out of the question" only because I have an immensely handy husband). But then I showed Jimmy some closeups of the window frames in question, whereupon he realized that I had nice new windows ("Oh, you have thermopaned windows!" "...is that what they are?") and that changed everything. It turns out, I can basically build the windows as zinc-framed panels, and caulk them puppies right into the window frame in such a way that the crank opening thingie (er, "casement?" there's a whole world of window-related terminology I never knew about) still works, opening up the stained glass itself, while retaining the double-paned clear glass behind it. This is a good thing because: 1) stained glass windows that actually move on functional hardware are way cool---I'm so glad we did the transoms that way, where by "we" I mean "Don". 2) Jimmy says he thinks I can get away with no rebar at all. The double layer of window glass behind the stained glass will provide enough protection from the weakening elements of sun and wind and etc. that Jimmy says I can just use reinforced lead came, which has a heart of brass for more structural support than lead alone offers. 3) You don't have to stretch reinforced lead, which means I won't end up bruising my coccyx on a concrete basement floor. 4) No surgery on my window frames is required. Jimmy recommends DAP Dynaflex 230 caulk for the job. He says duct tape the window in enough to hold it up, caulk it in, let it dry, peel the tape, and you're good. The internet says Dynaflex 230 is paintable, a bonus. For years, I have heard stories from Don about how his dad's answer to all home fix-it chores was "caulk the shit out of it." I have in fact been given many times a pop quiz in which the question sometimes varies, but the answer is constant: "caulk the shit out of it." This seems a close cousin to the common sentiment, popularly held by a certain type of solid, can-do, red-blooded American guy, that duct tape can fix anything. And so it seems that here tonight I have achieved the holy grail of male odd-job know-how: a job whose sole two agents are caulk AND duct tape. I have the strongest urge to crush an empty beer can on my forehead. So basically I now have all my pressing construction questions answered, and there's nothing stopping me from diving right in. Honestly, I expected to end up asking Jimmy if he does any kind of private lessons, for me to learn how to use rebar. His spring class at Art League is about over, and the summer class doesn't start for a month, even if I thought I needed nine weeks of instruction. But I got everything I needed tonight in less than half an hour. A less generous teacher would have looked at my finished design and my fifty-dollar glass-buying spree and seen a captive audience of one, a tuition check in red beaded sandals. And that's why I'm certain I've blogged nary a negative word about one Mr. Jimmy Powers, stained glass artwork & repair, summer classes at the Art League School of Alexandria, VA beginning at the end of June. Wednesday, May 24, 2006: Window Clarity

A comment on the Glass Chat board about my last entry cautioned me against laxity in installing my dogwood windows (caulk bad, screws and stops good). It made me think I should clarify a bit. A picture's worth a thousand words:

The part of the window that actually opens up is built in such a way that the glass is inset into a kind of recessed frame, leaving a lip maybe half an inch deep all the way around the glass where my stained glass panel can handily rest, and be affixed accordingly. I thought I'd clarify in case anyone got the idea that you could use caulk to "glue" a stained glass panel to a window frame, without there being a lip or channel of some kind for the panel to rest on. I don't want to be responsible if someone tries it and ends up with their stained glass in shards on the floor! Wednesday, May 31, 2006: Holding Pattern

It's not that I lost steam on the dogwood windows project after getting only as far as buying nine square feet of glass. It's that I don't have a place to work. At the old house, the unfinished basement was full of ancient, dusty, ugly cabinets and benches and tables (including a small mirrored medicine cabinet with little pots and vials of things like mouthwash and shaving cream and pain relievers that dated, I'm guessing, from the 1940s and 1950s). One of these antiques, an unpretty but solid work table, was perfect for stained glass work. It had been there since long before Don bought the place, and now that we've sold it, there it remains. It didn't seem worth moving, but I'm kind of kicking myself now, because the basement at the new house is all drywall and recessed lighting. Nary a dusty, unused workbench in sight. Nothing's stopping me from going to IKEA and getting a cruddy little laminate table, except, well, maybe I'm cheap but spending sixty dollars on furniture that's just going to end up covered in glass dust, solder balls, and lead came scraps? I can't bring myself to do it. So I've been hovering around the furniture ads on Craig's List and the local Freecycle boards. I failed to move quickly enough on two good candidates there, which will get old fast if the pattern continues. Don had suggested a trip to Rough and Ready at 14th and T Streets in Shaw---a Sanford-and-Son-esque cave of dusty used furniture stacked to the leaking ceiling. But I reminded him that Rough and Ready was gentrified away recently, the entire block purchased for a planned condo development, and I know of nothing else like it. I may have to break down and get Don to build something for me. Plywood and two-by-fours: stronger than IKEA laminate and aluminum, yet vastly less expensive. Why didn't I just ask him in the first place? Well, he's been busy, cleansing his palette after the couch project with an amusing little Mission end table, something he can do with one table saw tied behind his back you understand. It's almost done now. When the furniture Don is building suddenly looks like something purchased at Abu Ghraib's Going-Out-Of-Business Sale (all torture implements must go!), that means glue-up is in progress.

And if glue-up is in progress, the end is in sight. I'll wait a few days for Don to put a finish on his end table and call it done; if by then my own Craig's List want ad hasn't resulted in a beefy workbench big enough to hold two 15 by 33 inch windows-in-progress, it'll have to be handy husband to the rescue. Sunday, October 15, 2006: Breakdown; Regroup

It was May when last we spoke. May: a good month. In fact, a very good month. Lucky thing, that: the other 8 1/2 months of this year have been, by and large, absolutely unbearable. My beloved Zima cat (whom you may remember as my occasional glass-shop assistant) died on March 31, at eleven and a half years old; she'd been mine from a tiny kitten. She lost a short but ugly fight with cancer, which had first appeared in early March. She became ill the same week that my beloved Shadow dog (whom you may remember as the dog we adopted to keep Tashi from eating any more furniture) also got sick. His illness was harder to identify, and so we tried every treatment for every symptom. For weeks this went on: I gave him pills and shots and subcutaneous fluids and force-fed him and cooked special food for him and logged hundreds of road-miles back and forth between home and various vets. I dropped the classes I was taking; I cut back on work. In my grief at losing Zima, it was out of the question to give up on Shadow. Bless Don's sweet, kind heart: he understood. In April, it finally began to seem as if all our work had not been in vain. The vets were throwing around words like "miracle." Slowly the daily course of medications and special foods slackened, until there were no more shots, no more fluids, and far less scrapple and lunchmeat in Shadow's food bowl. In mid-May, Don and I took a week's vacation in West Virginia. We took the dogs with us. Shadow and Tashi climbed mountains and strained at deer and jumped in lakes like natural-born athletes; Don said Shadow was in better shape than we'd ever seen him. While we were in West Virginia, Shadow began to eat plain old dry food again, for the first time in two months. In late May, I felt like the misery of trying to keep on top of work, school, and wifedom simultaneously with grieving for one pet and fighting for another's life was finally behind me. For the first time in months I could look into the future at a point farther out than a day or two, and be unafraid. It was during this time, for example, that I began to formulate plans for the dogwood windows project: it would be a big one, but hey, nothing compared to staring the grim reaper in the face and telling him he'd been a houseguest for long enough; his impositions upon my family had grown tiresome; don't let the door hit you in your ass on the way out. On about June 7, Shadow developed a cough. On June 11, Shadow died of congestive heart failure. I lost my shit completely for a while. I had given everything I had to trying to save Shadow; I had nothing in reserve for taking care of myself in the event that I should lose that fight. Stained glass was not at the top of my to-do list. Now, here we are. Four months later. I guess I'm about through the process of crawling out of the deep black hole I've been hiding in. In July, we adopted a new husky to keep poor lonely Tashi company; last week we adopted a new cat for no real better reason than that no one else wanted her and she'd spent months in a 2x2x2 cage at PetsMart. My sporadic fits of crying are much reduced, although the junk food/comfort food habits of the spring and summer seem to be sticking around for the long haul. Last month I had a birthday (30, for which the most appropriate celebration seemed denial, so I dyed my hair neon punk-rock red). As my gift, I asked Don to build me a workbench for glass work. Et voila:

The only must-have functional feature of the workbench as I proposed it to Don was a couple of very, very shallow shelves, just tall enough to slide in a plywood workboard containing stained-glass-in-progress. You would think that cats would neither walk nor nap on top of little pieces of cut-up glass, but experience has taught me otherwise, so these cat-proof shelves are absolutely key. As Don built them, they are just perfect, and I am most tickled. Handy husband to the rescue, indeed. In the last week, I've visited Weisser Glass twice. They moved into a new location while I was laid low with grief and self-pity; the new space is at least four times the size of the old one and I find it sort of intimidating somehow? Like, if I was going to peel my sad self off the couch long enough to come patronize your business establishment, the least you could've done was kept the old, familiar, cozy, safe store just long enough for me to get my bearings. Gosh, I sure hate it when the world doesn't revolve around me. But anyway, I have purchased a bunch of nifty things:

Still need to procure plywood workboards on which to build the windows, and a zinc saw, or a plain old hacksaw with a 32 TPI (teeth per inch) blade, because the rust that got my old nails also got my old zinc saw. And still need to finalize life-size production patterns; I keep procrastinating on that because I'm not actually sure whether the oak framing is appropriate for this project (might make installation harder). If I don't use it, that affects the width of the window, which affects the pattern, which makes my head swim with the effort at keeping straight the math, in sixteenths of an inch. I actually got really good at fast conversion and addition of eighths into decimal while Shadow was sick, because once he started eating again, I measured and logged everything he ate or drank. For some reason I chose to draw the line at recording in sixteenths of a cup. Because filling up the lower half of homemade Microsoft Word medication logs with tiny print recording the helpings of chicken, beef, rice, kibble, canned food, scrapple, lunchmeat, and cheese that my dog ate each day for two months in increments of a relatively fast and loose 0.125 cups is clearly on the safe side of the crazy line, right? Posted by Michelle at 08:05 PM

| Comments (6)

Tuesday, October 24, 2006: 3 Photographs

Workboards? Check. Hacksaw blade? Check. Actual decisions on framing? Check. Production pattern? Getting very close. I don't know, kids, if I didn't know any better, I'd say this was starting to look like a glass project.

Also, it was pointed out to me that I was remiss in not providing photos of the new doggie (named Polar), the new kitty (provisionally named Sassy), or the new hair (named "total lack of upward mobility"). Since time for a typical rambling glass-work entry is most scarce indeed this last week or so, I might as well oblige:

Posted by Michelle at 12:18 AM

| Comments (3)

Sunday, November 05, 2006: A Thousand Words

So, when we moved from the house in DC over two years ago, my AA battery charger somehow made the trip minus its power cord. As a result, usage of my "good" (i.e.: old, but capable of exquisite quality) digital camera fell off sharply. That's the one that can focus in on something from a few inches away. That's the closeup camera. Maybe a year ago, I was standing in line at a Rite Aid a couple of miles away with a new battery charger in my hands. I had stopped in to buy cold medicine or something, and happened to see a battery charger, and decided to impulse-purchase it. But I'd forgotten the reason I rarely go to that particular Rite Aid---it's so goddamned slow---on this particular day I got so tired of waiting that I eventually dumped my battery charger and toilet paper or whatever, and sashayed out the door. I recently heard that the sordid little mini-shopping center where the Rite Aid is located may be torn down in favor of some glass-walled high-rise monstrosity; it's only with the smallest pang of conscience that I say good riddance. I've been meaning for days to write a new entry about where things stand with the dogwood windows, but it needed pictures, and the little camera wasn't up to the job, despite its possessing the virtue of a convenient charging cradle. So the other night I went out to buy batteries at my friendly neighborhood corporate megalith drugstore, and lo and behold, they too now carry battery chargers. (They didn't used to. I'd looked.) Brought one home, charged up a pile of AAs, and dusted off the good camera for the first time in months. That is how it came to cost me twenty-two dollars to find out that my good camera is dead. So I'll have to talk you through the glass update. Once I had a draft production pattern all printed out at 100% and laid out on the workboard, it really hit me how small some of the pieces were. One round piece which repeats throughout the pattern is just 10mm wide; another repeating round is 15. So I had to ask myself whether I'd be able to bend lead around such a small piece smoothly enough that my circles would look like circles and not, you know, misshapen vaguely round messes.

I cut some test pieces of glass, and also bought some glass jewels in a few different sizes to test out as well---I've been thinking I'd like to use some basic faceted jewels rather than cut glass for the round pieces---and started trying to wrap lead around them. I started out working with a 15mm jewel. Turns out, even at 1/8" lead (which is in theory so skinny it's easy to bend), it's tough. The lead doesn't want to bend around in a nice uniform circle. Remember the episode of Six Feet Under where Claire complained that her art professor had her drawing freehand circles all day long? I could see how such an assignment would be frustrating and dull, but I could also see how such an assignment would be valuable because a nice *clean* freehand circle is really hard. Go ahead and try it now. Do your best. Whatever you come up with, it won't be a proper circle, and whatever you come up with, that's about how my 1/8" lead wanted to bend around my 15mm jewel.

It was a little easier with a 20mm jewel, and actually I managed to get very nearly a perfect circle with a 25mm jewel. So I thought, fine, I'll just scale up both of the circle elements in my design. Rock on, right? Except the design looks all wrong when I do that. It throws off the proportions of everything else. Like so:

The original proportions are on the left; on the right the four circles at the edges are scaled up from 15mm to 25mm, and the circle in the center is scaled up a little bit too. I don't know quite how much because as soon as I saw how my pattern got uglied up when I scaled up the edge circles, I sort of threw up my hands and stopped working with the pattern then and there. That was days ago, and that's where it stands now. I don't quite know what to do. I liked my original proportions very much. I can't make the windows in my living room any bigger, obviously. I could try to do a window consisting of 3 vertically stacked, larger versions of my pattern, but I like the more intricate 2x5 better. And I already bought glass according to measurements on the 2x5s, so I don't want to stray too far from those. Maybe I could do these windows in a copper foil-lead hybrid rather than in lead only? Foiling my small circles would eliminate the need to bend lead around them, but uch, I don't even like foil work, I surely haven't ever tried to combine the two methods; I don't think I want to go there. I don't know. I'll figure it out. But until I do, I can't build a thing. Posted by Michelle at 06:21 PM

| Comments (3)

Tuesday, November 14, 2006: Spinning in Circles

I'd about decided that I was going to have to suck it up and do the dogwood windows in a combination of lead and foil in order to stay true to the nice proportions I'd designed---my little circles were just too little to be very lead-friendly. It was not without a generous helping of pout-and-whine that I made this decision. It seemed like I'd want to foil about half of each 200-piece-plus window, and if anyone ever tries to tell you that copper-foil stained glass work isn't tedious, they're lying, I say: lying. So I went ahead and drew a final production pattern. Blue lines for lead, red lines for copper.

And then someone offered a thin ray of hope. A gentleman named Tod Beall who haunts most of the stained glass forums on the web, as far as I can tell, made a fiendishly clever suggestion via the Glass Chat board: You CAN lead those little circles and the 1/8" round [H lead] is perfect for it. Find a round object close to the size of the circles, maybe the body of a marker, or 1/2" dowel. Wrap the lead around this object several times (the number of circles plus several extras) in a tight spiral or coil. Handle with care; I often cut the lead while still on the form using an Xacto backsaw, but you could use lead dykes also. Start with one full circle (loose the straighter end and just cut from curved portions), cut it free and see if it fits your glass. Adjust and trim excess if necessary. If it's too short, cut the next one a little longer. This is an old trick and it works very well. Of course, it's always easier to shorten one that's too long.... Genius! Or that's what it sounds like anyway. I haven't tried it yet. I think I will tonight. Don was trying to decide whether to go to a Krav Maga class or a work-related happy hour (his customer these days is the happy-houringest federal government agency in Washington). But I might've trumped both options. My successful deployment of feminine wiles consisted of suggesting that we could spend the evening in the basement together, me playing with my stained glass, him playing with his latest woodworking project. Who could resist, I ask you? No husband of mine, is who. In parallel to trying to figure out how to actually build what I've designed, I've also been trying to figure out how to create water-resistant, reusable pattern pieces. Remember that the glass grinders used to smooth and tweak the edges of cut glass are water-cooled; if you use the paper-pattern method of glass cutting (rather than the lightbox-and-tracing method, whose practitioners smugly trumpet their superior technique but which doesn't work nearly so well for someone with unsteady hands, e.g. me) you'll end up soaking your cutting pattern pieces, and ruining them if they're plain paper. For all the time it will have taken to draw and cut such a complex pattern, I'm not up for doing it twice---I wanted to be able to peel my pattern pieces off of Window #1 as it was assembled, and use 'em again for Window #2. Options abound here: draw on clear vinyl, or have a sign-making shop with a cutter-plotter produce pre-cut vinyl pattern pieces from your design, etc. I opted to pick up some clear Mylar from Michael's with which to "laminate" my pattern pieces, using spray adhesive. Took some experimentation to come up with a process which didn't result in chemical obliteration of my Sharpie lines by the spray: the secret is to spray the Sharpied pattern piece with the adhesive and let it sit for a few minutes to partially dry before affixing the Mylar. Here's something else about Mylar: one piece is clear, but 25 clear sheets (as in the package I bought) are an almost-perfect mirror. Aaaand, if you bend the Mylar around, it becomes a funhouse mirror. Behold the result of my inability to resist shiny objects:

My head is amoeba-shaped. Awesome. Also procured last night at Michael's: five new Sharpie markers in colors I didn't have before. Riches beyond my wildest dreams: markers make me unaccountably, gleefully happy. Posted by Michelle at 05:18 PM

| Comments (2)

Friday, November 17, 2006: Tod Beall Is My Hero

That tip on how to handle leading very small circles? Completely awesome. Screw the copper foil... we're back to Plan A, which is All Lead All The Time.

Glory hallelujah. The color-coding on my production pattern will still be useful. Instead of describing copper lines and foil lines, it'll now be red = 1/8" H round lead, blue = 3/8" H round lead. I have about a ton of 3/8", will have to buy more 1/8". Also a new 1/8" grinder bit, to carve out the little nicks on the ends of the dogwood petals: I have one, but it's missing a tiny little screw that holds it in place, and so it's wobbly to the point of wanting to launch itself off the grinder and across the room mid-operation. Also 26 15mm round faceted red jewels. Some women buy shoes... Posted by Michelle at 11:27 AM

| Comments (1)

Sunday, November 19, 2006: Squint And Pretend

I've "laminated" my workboard pattern using the Mylar sheets I bought. This will make it resistant to smudging and running that would otherwise be the result of laying wet-from-the-grinder pieces of glass on top of it during construction. It also made the pattern stiff enough that I could stand it in one of my casement windows to do a size check.

Nifty. Um, although, this photo does nicely illustrate the way the decorative internal grids between the panes of the thermopane windows will show through my stained glass, rather awkwardly I expect. I had seen that coming, and at first thought maybe I'd see about getting an estimate on having the windows replaced or even just the grids removed, as the windows are actually in top condition. Then I figured the cost would probably be ridiculous just for the sake of showing off my stained glass, so I tried to ignore it. But looking at this photo... maybe there's no harm in just getting an estimate. I bought a pile of 1/8" H round lead came yesterday, ordered a bunch of red 15mm round faceted glass jewels, and the nice folks at Weisser Glass steered me away from purchasing a replacement grinder head to fix my missing-screw-wobble problem---turns out they sell a "Glastar grinder accessory kit" of small pieces that cost me a quarter of what a new head would have cost. Now my grinder head cannot become a high-speed projectile, no matter how much it may desire to do so. Next up: cutting up pattern pieces. Woo. Posted by Michelle at 10:56 AM

| Comments (0)

Wednesday, November 22, 2006: Jewels Ahoy

My jewels came. They're faceted, and so they're sparkly, and so they're unreasonably fun to play with. But they're also really tough to get a decent picture of with my one functioning camera.

Also in the photo is a little triangle of red glass left over from the crocus panel. I'll need to cut a whole pile of teeny little half-circles, half the size of my jewels, for the places in my design where red circles are cut off by the zinc frame. It's not that you can't cut the glass jewels---you can---it's that at their thickest points, they're a lot thicker than regular glass; they won't slide into the channel of the zinc framing. So I'll be using some leftover red cathedral glass in those places; the color match isn't 100% exact but those pieces will be so small that the mismatch will only be noticeable if you're looking. I also made some phone calls today to find out about replacing my IGU's. That's window-biz jargon (which I learned about twenty minutes ago) that stands for "insulated glass unit." You may recall, my existing IGUs are of recent vintage and in fine working order, but they have that pesky "decorative" grid between the two panes of glass that would end up showing through my stained glass panels and bugging me 'til the end of time. After some dead ends along the lines of "we have a 5-window minimum" and "we don't work in Silver Spring," I got in touch with a nice lady named Jennifer at Rockville's Bel Pre Glassworks, a company with a glass cutter incorporated into their logo, which made me smile because I'm a nerd. Jennifer was far more patient and helpful than I had any right to expect, given the scope of my itty-bitty two-window project. To order new IGUs, which I or my handy husband would need to install ourselves, she ballparked me a price of just under sixty-eight dollars a window for tempered safety glass, or just over forty-five for annealed glass, per. That's way less than I was afraid of; some prices I saw online for complete, DIY casement windows (including frames and sashes and other stuff I don't need) were in the $175 per window range and that wasn't going to fly. But if I can banish my grids for ninety bucks? Might just. Here's the fun part, though: to be absolutely 100% sure that what we order has the right measurements, the best thing to do is going to be to take our IGUs right out of their frames and take 'em up to Rockville to have a pro get all the dimensions. Doesn't look like that'd be hard---just a few screws---but see, it's about to be December out there (in fact, today's weather feels more January to me). And this time of year, you really want to have glass actually in your window frames. If I had the windows out of the frames for as little as an hour, I bet that'd be plenty time enough for it to get very, very cold in my living room. I guess some heavy-gauge contractor-style trash bags and duct tape might suffice for an afternoon, but those windows are on the side of the house facing the retired guy whose self-appointed job it is to police the lawn maintenance and general upkeep of every home on the block, and I think having trash-bag window panes, even temporarily, will send my poor neighbor right over the edge. I will have to consider the pet containment implications of having a couple of 14 by 32 inch holes in our living room wall, as well. Although I kind of wouldn't mind if one of the cats got out, if it were just long enough for them to realize "the warm's in the house, and the food's in the house: oh crap." Teach 'em a valuable lesson. Posted by Michelle at 03:07 PM

| Comments (1)

Saturday, November 25, 2006: Anal-Retentives Apply Within

A couple of days ago, I began the process of faux-laminating my cutting pattern with Mylar and spray adhesive, and then the actual cutting. It's tedious work, not to mention sticky, and I didn't get too far before telling myself that I really needed to know that the laminated and cut pieces would hold up on the grinder before going so far as to cut out all 230-odd pieces. So I located the first couple of pattern pieces according to building order, and cut some glass accordingly. Indeed there were a couple small process kinks to work out there, having to do with the need to spray pattern pieces and glass, then let them sit for a couple of minutes to partially air-dry before putting the two together, for maximum stickiness. With previous projects my pattern pieces have been just plain paper, affixed with glue sticks, but the combination of glue stick and Mylar just makes a slippery mess that slides around all over the place on the grinder. And actually, about the same thing happens if you try to slap together a Mylar-ed pattern piece and some glass immediately after applying the spray adhesive. So I got that all worked out, and thought about laminating and cutting the rest of my pattern. And then I told myself that I really needed to know that the repeating design motif of my pattern was truly buildable in lead---it is, as I have mentioned before, of a sufficiently small and picky scale that copper foil would for most people probably be the more natural choice here. And so I began leading.

If it all sounds like I may be experiencing a certain amount of impatience with regards to laminating and cutting my pattern, there might just be something to that. That's not the fun stuff. Leading is. Still, it's not all excuses and rationalizations here. There's definitely a bit of a learning curve going on as I fight my way through the leading of my first dogwood shape, especially since I'm working in lead with only a 1/8" face width around the flower: that leaves almost zero wiggle room for hiding mistakes. I'll want to lead in one of each of my problematic little circles (the light green dogwood centers and the red faceted jewels) before I consider myself to have walked through a successful and complete proof-of-concept, but it got late, and I have no idea how well the noise of my glass grinder may carry. Our neighbors live frightfully close; I may have mentioned before how I am sometimes awakened early in the morning by the sound of the neighbor lady sweet-talking her mildly neurotic Labrador retriever. Must address the camera situation soon. While doing a bit of web research to try to be able to quantify in precise technical terminology what I love about the big old broken camera and what I hate about the tiny less-old working camera, I discovered that the T.L.-O.W.C. has what's called a "fixed focus" lens, which is supposed to be result in more-or-less in-focus photos "from one meter to infinity." Aaaaand, there's my problem. For purposes of this here little weblog, having to take photos from a meter away is pretty much unacceptable. So whenever I break down and begin shopping for a new camera (ideally with a large pile of cash dropped by the gods from the sky for that exact purpose?), I will know to avoid that. It's a shame, though, in a way---I also learned that the fixed focus is a big part of why the little camera (Casio Exilim, second-generation) is so beautifully fast. The camera ex machina, thus, will necessarily have to be a slow(er) one. It's a lot like the primary rule of reasonable expectations that is much quoted by web developers and probably folks in many, many other professions: of Good, Fast, and Cheap, a client/consumer may ask for, and in fact receive, precisely two. Posted by Michelle at 10:55 PM

| Comments (0)

Sunday, November 26, 2006: Proof-of-Concept

Monday, December 04, 2006: Stolen Time

Why is it that every time I get really grooving on a stained glass project, every client I've ever had comes out of the woodwork needing me to write code for them? For the last week, I've been sneaking down to the basement to do ten minutes at a time of leading. "Oh, I have to, uh... check the laundry. Right! Down to the basement I go, la di da..." You can get a decent amount accomplished this way. Denial is your friend.

I now have approximately 28% of the first panel leaded. Fitting in that big red-purple diamond in the middle felt good, let me tell you. Notes to self: never ever again buy Spectrum 100K crackle glass. The ripply veins of texture are so pronounced that they make the glass thicker, in places, than you can fit into a lead came channel. So I've been having to use my grinder in ways that this particular grinder was never meant to be used. I always wondered what was the point of a disc grinder. Now I know. Also, the mystery Wissmach glass I'm using for my flower petals has a texture problem all its own. Both sides are very finely stippled, as opposed to the mirror-smooth finish on the "cutting side" of Spectrum glass. This makes cutting slightly tougher on the Wissmach, but not enough to be a big pain. No, the big pain is trying to get spray adhesive off the Wissmach, an experience that I imagine is similar to trying to get bubble gum off of concrete. I don't know how much time I'll have left to steal for the rest of this month. For every item I cross off my to-do list, two more arise to take its place. As for Christmas, I'm pretending it doesn't exist. I don't have time for so much as a bah humbug. Although we did break out the red-velvet-and-white-fake-fur Christmas jingle collars for the dogs the other day, and watching Polar spin alertly in circles, wearing his collar and trying to figure out where the noise was coming from was, I'll admit, pretty darned festive. Posted by Michelle at 10:24 PM

| Comments (1)

Friday, December 08, 2006: We Have The Technology

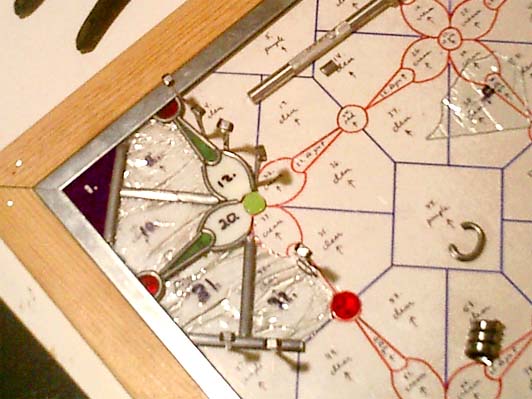

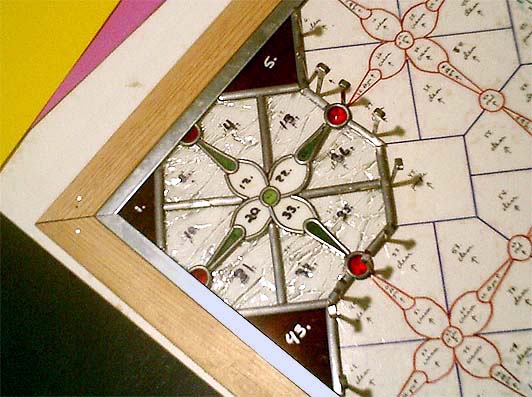

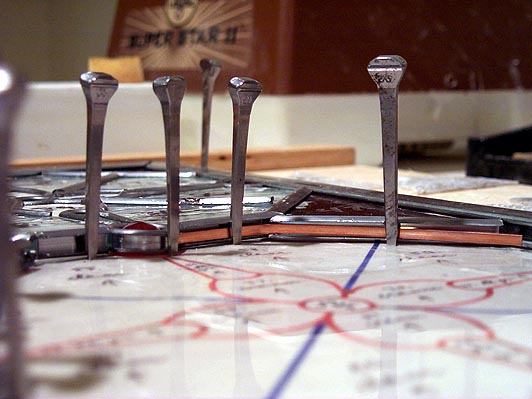

My big old brick of a digital camera wasn't broken! Instead, it was the card that was bad. In technical terms: it went kerflooey. Celebrate with me, won't you? Herewith: a few up-close-and-personal photos of dogwood window #1---now 30% leaded---for no reason other than that I could.

Posted by Michelle at 05:24 PM

| Comments (7)

|

||||||

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

||||||||